Glow-worm ULTIMATE 30c Manuals & User Guides. User Manuals, Guides and Specifications for your Glow-worm ULTIMATE 30c Boiler. Database contains 2 Glow-worm ULTIMATE 30c Manuals (available for free online viewing or downloading in PDF): Installation and servicing manual, Installation and servicing.

44

11 Commissioning - Nat. Gas (G20) to LPG (G31) Conversion

11.10 LPG CONVERSION - all models

IMPORTANT: Gas conversion must be carried out by a

competent person approved at the time by the Health and

Safety Executive.

Isolate the boiler from both the Gas and Electricity supplies.

The burner must be removed from the boiler by removing,

the front panel, hermetic chamber cover and combustion

chamber cover. Remove the two securing screws, one on

each side of the burner, see diagram 11.13.

The old injector bar (manifold) must be removed.

The ignition electrode and flame (ionisation) electrode

cables must be removed by opening the control panel and

gaining access to the PCB. Disconnect the plugs of the

ignition and flame (ionisation) electrodes, see diagram

11.15.

Fit new injector bar (manifold), new sealing washer and

tighten, ensuring that the injector size is marked 0.75 mm for

LPG (both for Betacom 24c and Betacom 30c)

Fit burner and re-assemble.

The joint must be checked for Gas Tightness.

14555

Diagram 11.15

FLAME AND IGNITION

ELECTRODE LEADS

14566

Diagram 11.14

SENSING TUBE

GROMMET

BURNER

14557

Diagram 11.13

SECURING SCREW

LEFT HAND SIDE

OF BURNER

RIGHT HAND

SIDE OF BURNER

Remove the gasket of cables with the cables inside.

1 2 3 4 5 6 7 8

ON

DIP

1 2 3 4 5 6 7 8

ON

DIP

DIP SWITCH

OFF POSITION

DIP SWITCH

ON POSITION

1 2 3 4 5 6 7 8

ON

P7

P5

P2

P4

DIP

8 DIP SWITCHES IN

THE OFF POSITION

MAIN PCB

Diagram 11.16

39

1

2

3

4

bar

0

1

0

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

24

23

ON

30

40

50

60

70

80

90

bar

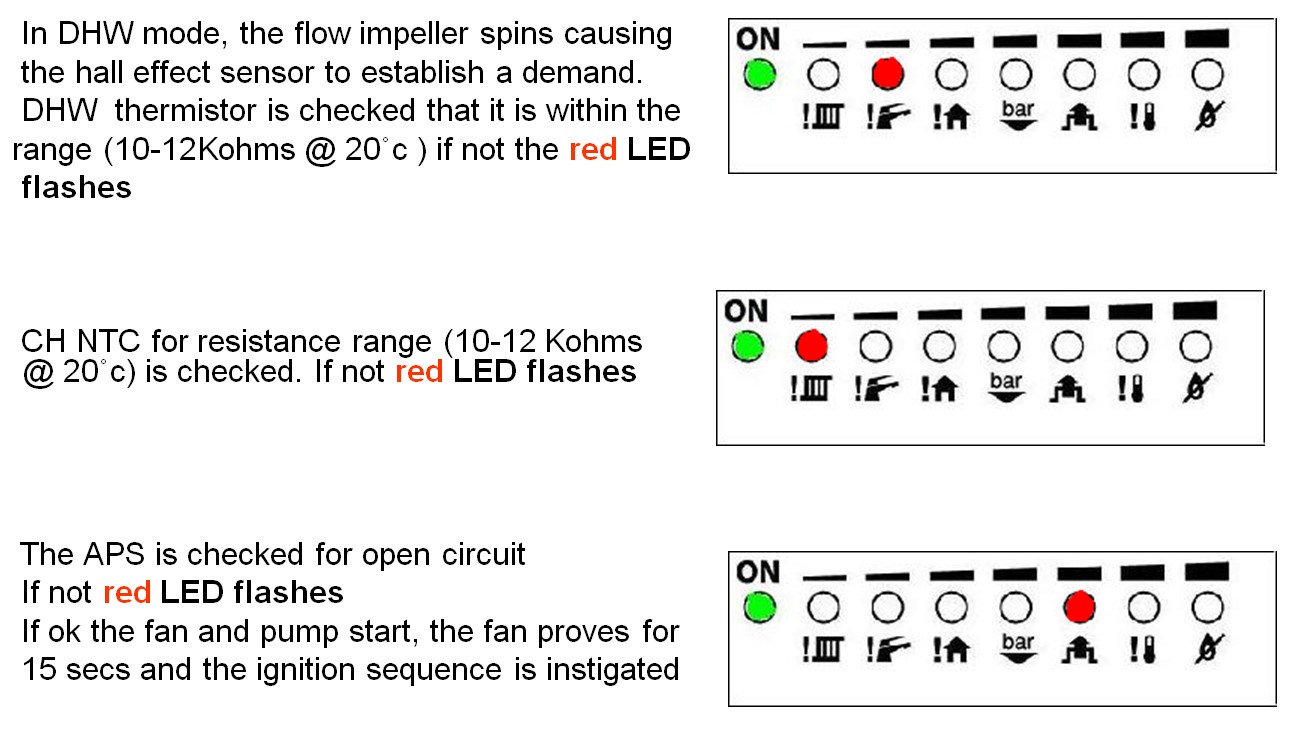

11 Commissioning

11.3 Control Panel Functions, diagram 11.4.

Central heating and domestic hot water temperature

controls: The boiler’s integral control unit monitors and

adjusts both the boiler’s hydraulic circuit and D.H.W. water

outlet temperatures by means of sensors located on the

CH heating and D.H.W. flow outlets. The sensors electrical

resistance, which is dependant on temperature, determines

the current passing through the control potentiometers

located on the control panel. The respective potentiometer

control dial allows manual setting of the maximum required

temperature (reference value) being between 30º and 85ºC

for CH heating and 35º and 64ºC for D.H.W. When the boiler

operates in heating or D.H.W. mode, the current received is

compared to the manually set reference value. The difference

of the two values operates the modulation of the gas valve

adjusting the useful heat output generated and stabilising the

temperature to within ±1ºC.

Re-set function: Should the boiler lock out at any time,

please check the gas supply and ionisation probe position, the

boiler may be re-started by switching to standby “O” position

waiting 15-30 seconds.

Switching back to its previous position once the fault has been

eliminated.

Function switch: The three position switch allows the boilers

operation to be set to ‘Stand-by’ (centre position), ‘Heating

+ D.H.W.’ (left hand position) or ‘D.H.W. only’ (right hand

position).

14333

Diagram 11.4

11.3 Commissioning

The Betacom 24c and 30c boilers have been tested and pre-

set at the factory and is dispatched with its on board controls

set to provide a maximum central heating and D.H.W. output.

Consequently, once all the connections have been made and

the boiler has been filled with water to the designed system

operating pressure, the boiler may be fired prior to adjusting

it’s on board parameters to match the heating systems

requirements.

11.4 Initial Lighting

Glow Worm Betacom 30c Installation Manual

Prior to firing: Check that the electrical supply to the boiler

is ‘On’ (The green boiler ‘Stand by’ indicator will light) and the

gas service isolation valve is in the open position, see diagram

11.1.

Set the boiler’s central heating and domestic hot water

temperature controls to maximum by turning them fully

Glowworm Betacom 30c User Guide

clockwise.

Set the external room thermostat (if fitted) to maximum and

open the thermostatic radiator valves to maximum.

Switch the boilers function switch to the central heating and

domestic hot water position. The boiler’s control unit will

now automatically carry out pre-ignition safety checks before

igniting the burner.

TIMER

DISPLAY

STANDBY

INDICATOR

PRESSURE GAUGE

FUNCTION

SWITCH

CENTRAL HEATING

TEMPERATURE

CONTROL

DOMESTIC HOT WATER

TEMPERATURE

CONTROL